Stainless Steel Spray Balls Manufacturer in India

Stainless steel spray balls are specialized sanitary cleaning devices designed to provide 360-degree coverage for automated cleaning-in-place (CIP) systems in tanks, vessels, reactors, and process equipment. These precision-engineered devices deliver high-impact spray patterns that ensure thorough cleaning of internal surfaces without manual intervention, making them indispensable in pharmaceutical, food processing, dairy, beverage, biotechnology, and chemical industries. Available as SS spray balls, sanitary spray balls, hygienic spray balls, and rotating spray balls, these cleaning solutions are manufactured to meet the highest standards of hygiene, efficiency, and durability.

Stainless Steel Spray Balls Manufacturer, Hygienic Spray Balls Manufacturer India, SS Spray Balls, Sanitary Spray Balls Supplier, Spray Balls Suppliers In India, SS 304 Spray Balls, SS 316 Spray Balls, Spray Balls Exporters, Spray Balls Manufacturers, Spray Balls Stockist, Spray Balls Suppliers In Mumbai, CIP Spray Balls, Tank Cleaning Spray Balls, Rotating Spray Balls, Static Spray Balls, Fixed Spray Balls.

One of the most effective variants is the rotating spray ball, which features a self-rotating mechanism powered by liquid flow, ensuring comprehensive coverage of large tank surfaces. The rotation is achieved through strategically positioned spray holes that create thrust, eliminating the need for external power sources. Static spray balls (also called fixed spray balls) provide stationary spray patterns ideal for smaller vessels or specific cleaning applications where rotation isn’t necessary. These spray balls feature multiple precisely drilled holes arranged in specific patterns to maximize cleaning efficiency while minimizing water and chemical consumption.

The CIP spray ball is specifically engineered for integration with automated cleaning-in-place systems, incorporating threaded or tri-clamp connections for easy installation and removal. These devices ensure repeatable cleaning cycles that meet regulatory validation requirements. The tank cleaning spray ball comes in various configurations including weld-on permanent installations, threaded removable types, and tri-clamp sanitary connections for applications requiring frequent inspection or replacement. Additionally, stainless steel spray balls manufactured from premium grades like SS 304 spray balls and SS 316 spray balls offer exceptional corrosion resistance against cleaning chemicals, acids, and alkaline solutions commonly used in CIP processes.

As a leading stainless steel spray balls manufacturer in India and trusted hygienic spray balls manufacturer India, we specialize in delivering high-quality cleaning devices that conform to international standards including 3-A Sanitary Standards, FDA regulations, EHEDG guidelines, and ASME BPE requirements. Our comprehensive product range includes various spray ball configurations designed for specific tank sizes, cleaning requirements, and industry applications. Whether you need sanitary spray balls for pharmaceutical reactors or hygienic spray balls for food processing tanks, our manufacturing facility is equipped with advanced CNC drilling, precision welding, and electropolishing capabilities to meet your exact specifications.

1/4″ NB to 24″ NB Seamless 1/4″ NB to 48″ NB Welded

SCH 5 to SCH XXS

ASTM A312, A249, A269, A270

Spray Balls Suppliers In India, Spray Balls Stockist In Mumbai, Spray Balls Stockist In India, Spray Balls Exporters In Mumbai, Spray Balls Exporters In India, Spray Balls Manufacturers In Mumbai, Spray Balls Manufacturers In India, Stainless Steel Spray Balls Suppliers, Sanitary Spray Balls Exporters, Hygienic Spray Balls Manufacturers, CIP Spray Balls Stockist, Tank Cleaning Spray Balls Suppliers, Rotating Spray Balls Manufacturers.

As prominent spray balls manufacturers in Mumbai and across India, we understand the critical role these cleaning devices play in maintaining product quality, regulatory compliance, and operational efficiency. Our position as reliable spray balls suppliers in India enables us to serve diverse industries including pharmaceutical manufacturing, biotechnology, dairy processing, beverage production, food processing, brewing, winemaking, cosmetics manufacturing, and chemical processing. We maintain substantial inventory as spray balls stockist in Mumbai to ensure immediate availability of standard configurations while also offering custom design and fabrication for unique vessel geometries and cleaning challenges.

Our role as spray balls exporters in India extends our reach to international markets across the Middle East, Southeast Asia, Africa, Europe, and North America. As dedicated stainless steel spray balls suppliers and sanitary spray balls exporters, we ensure timely delivery and comprehensive technical support including spray pattern analysis, flow rate calculations, and CIP system integration guidance. The SS 304 spray balls are ideal for general food processing and dairy applications offering excellent corrosion resistance at economical prices, while SS 316 spray balls provide superior resistance to acids, chlorides, and aggressive cleaning chemicals due to their molybdenum content, making them perfect for pharmaceutical, biotech, and chemical applications where cleaning validation is critical.

Global Export Network

As leading Spray Balls Exporters and Sanitary Spray Balls Exporters, we export worldwide to:

North America: USA, Canada, Mexico

South America: Brazil, Argentina, Chile, Peru, Colombia

Europe: Germany, France, Italy, Spain, Netherlands, Belgium, Poland, Austria, Switzerland, United Kingdom

Middle East: Saudi Arabia, UAE, Qatar, Oman, Kuwait, Bahrain

Asia: Singapore, Malaysia, Indonesia, Thailand, Vietnam, Philippines, Japan, South Korea, Sri Lanka, Bangladesh, Nepal

Africa: South Africa, Egypt, Nigeria, Kenya, Tanzania, Morocco

Oceania: Australia, New Zealand

Note: – All shipments are supplied with export-grade packaging and complete documentation.

Serving All Major Cities in India

As premier Spray Balls Manufacturers In India and Stainless Steel Spray Balls Suppliers, we serve:

Mumbai, Navi Mumbai, Thane, Palghar, Pune, Nashik, Aurangabad, Ahmedabad, Vadodara, Surat, Vapi, Ankleshwar, Bharuch, Dahej, Jamnagar, Rajkot, Chennai, Bangalore, Coimbatore, Hyderabad, Visakhapatnam, Vijayawada, Kochi, Palakkad, Thiruvananthapuram, New Delhi, Noida, Gurugram, Faridabad, Jaipur, Neemrana, Bhiwadi, Ludhiana, Jalandhar, Kolkata, Howrah, Durgapur, Haldia, Raipur, Bhilai, Nagpur, Indore, Bhopal.

Types of Stainless Steel Spray Balls We Offer

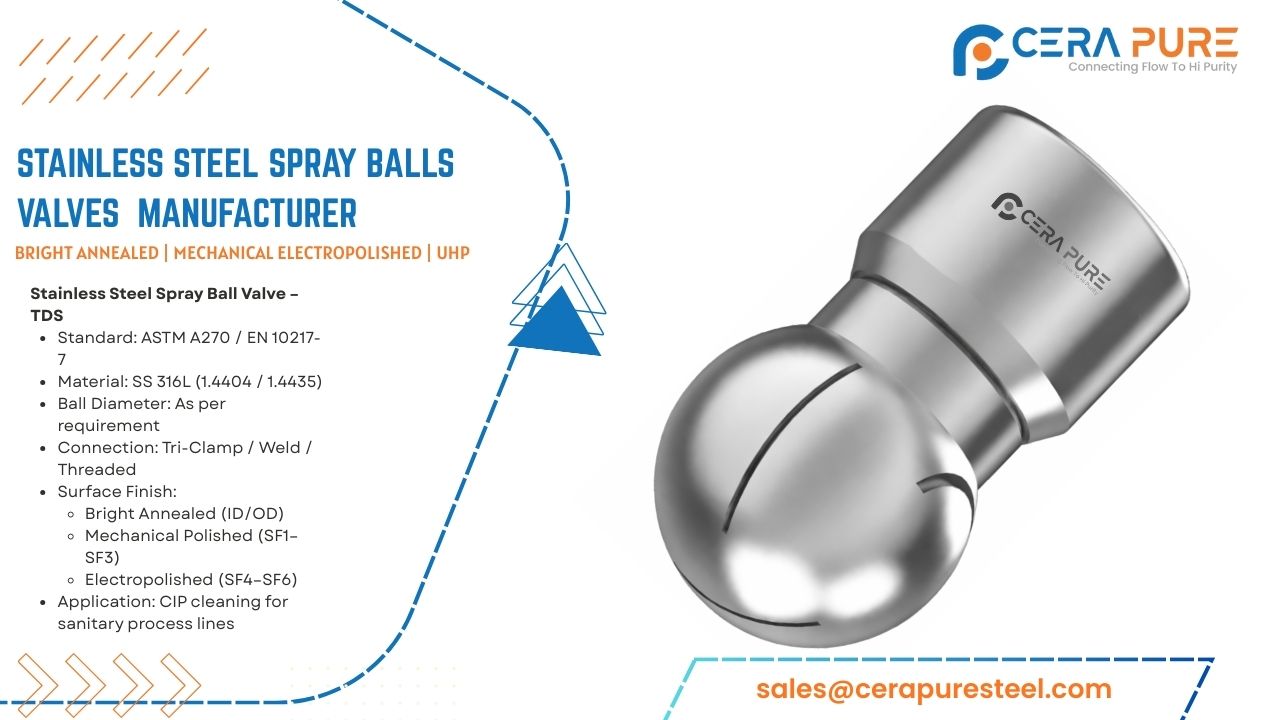

Stainless Steel Spray Balls Specifications

Parameter | Details |

Material Grades | SS 304, SS 304L, SS 316, SS 316L, SS 316Ti |

Diameter Range | 25mm to 300mm (1″ to 12″) |

Connection Types | Threaded (NPT/BSPT), Tri-Clamp, Weld-on, Flanged |

Hole Diameter | 1.5mm to 6mm (customizable) |

Number of Holes | 4 to 120+ (based on size and pattern) |

Flow Rate Range | 5 LPM to 500 LPM (size dependent) |

Pressure Rating | 2 to 10 Bar (30 to 150 PSI) |

Temperature Range | -10°C to 150°C (CIP/SIP compatible) |

Surface Finish | Electropolished, Ra ≤ 0.8 μm |

Standards | 3-A Sanitary, ASME BPE, EHEDG, FDA 21 CFR |

Spray Ball Types & Applications

Spray Ball Type | Mechanism | Coverage Pattern | Ideal Applications |

Rotating Spray Ball | Self-rotating (flow-driven) | 360° dynamic coverage | Large tanks (>1000L), fermenters, reactors |

Static Spray Ball | Fixed position | Radial 360° pattern | Small to medium tanks (<1000L), totes, IBCs |

Dynamic Spray Ball | Mechanical rotation | Controlled sweep pattern | Precise cleaning, large vessels, specialized equipment |

Single Piece Spray Ball | One-piece construction | Fixed hole pattern | Permanent installations, high-pressure cleaning |

Retractable Spray Ball | Extendable mechanism | Variable reach | Deep tanks, silos, difficult-to-reach areas |

Multi-Stage Spray Ball | Multiple spray zones | Layered coverage | Complex vessel geometries, tall tanks |

Spray Ball Size & Coverage Specifications

Ball Diameter | Recommended Tank Diameter | Typical Hole Count | Flow Rate | Spray Radius |

25mm (1″) | Up to 500mm | 6-12 holes | 10-20 LPM | 0.5-0.8m |

50mm (2″) | 500-1000mm | 12-24 holes | 30-60 LPM | 0.8-1.2m |

75mm (3″) | 1000-1500mm | 24-48 holes | 60-120 LPM | 1.2-1.8m |

100mm (4″) | 1500-2500mm | 48-72 holes | 120-200 LPM | 1.8-2.5m |

150mm (6″) | 2500-4000mm | 72-108 holes | 200-350 LPM | 2.5-3.5m |

200mm (8″) | 4000-6000mm | 108-144 holes | 350-500 LPM | 3.5-4.5m |

Industry Compliance & Standards

Standard | Application Area | Compliance Requirements |

3-A Sanitary Standards | Dairy & Food Processing | Material certification, smooth surfaces, drainability |

FDA 21 CFR Part 177 | Food Contact Materials | Material compliance, no product contamination |

ASME BPE | Bioprocessing Equipment | Surface finish SF4, documentation, validation support |

EHEDG Type EL Class I | European Hygienic Equipment | Cleanability validation, no dead legs |

cGMP Compliance | Pharmaceutical Manufacturing | Validation protocols, IQ/OQ documentation |

ATEX Certification | Explosive Atmospheres | Static-free operation, grounding provisions |

Equivalent Grades of Stainless Steel Spray Balls

STANDARD | WERKSTOFF NR. | UNS | JIS | BS | EN |

SS 304 | 1.4301 | S30400 | SUS 304 | 304S31 | X5CrNi18-10 |

SS 304L | 1.4307 | S30403 | SUS 304L | 304S11 | X2CrNi19-11 |

SS 316 | 1.4401 | S31600 | SUS 316 | 316S31 | X5CrNiMo17-12-2 |

SS 316L | 1.4404 | S31603 | SUS 316L | 316S11 | X2CrNiMo17-12-2 |

Being a premier hygienic spray balls manufacturer, we ensure every spray ball undergoes rigorous quality testing including dimensional verification, hole size inspection, spray pattern testing, pressure testing, and surface finish verification. Our CIP spray balls stockist inventory includes a wide range of standard configurations with both electropolished and mechanically polished finishes. As experienced tank cleaning spray balls suppliers, we provide complete technical support including spray ball selection calculators, flow rate recommendations, and CIP system design assistance to ensure optimal cleaning performance for your specific application.

Our rotating spray balls manufacturers division specializes in self-rotating designs that provide superior coverage for large fermentation tanks, storage silos, and process vessels. The rotation mechanism is engineered for reliability and longevity, with precision-drilled holes positioned to create balanced thrust that ensures consistent rotation speeds across varying flow rates. We also manufacture static spray balls with customized hole patterns optimized for specific tank geometries, ensuring complete surface wetting and effective removal of residues, proteins, and biofilms.

conclusion

stainless steel spray balls are essential components for automated tank cleaning and CIP systems in modern sanitary processing facilities. As your trusted stainless steel spray balls manufacturer in India, we offer a comprehensive range including rotating spray balls, static spray balls, CIP spray balls, and custom-designed cleaning solutions to meet diverse industry requirements. With commitment to quality, precision manufacturing, and customer satisfaction, we have established ourselves as preferred spray balls suppliers in Mumbai and throughout India. Our extensive experience as spray balls exporters ensures that you receive world-class cleaning devices backed by exceptional technical support, spray pattern validation data, complete material traceability documentation, and reliable after-sales service.